DEMCOPEM-2MW project completed!

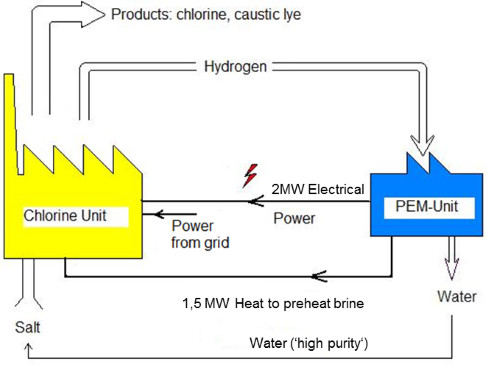

The world’s first 2MW PEM fuel cell power plant has been successfully designed, constructed and integrated into a chlor-alkali (CA) production plant, in Yingkou China.

The chlor-alkali production plant produces chlorine and caustic soda (lye) and high purity hydrogen. The hydrogen contains almost 45% of the energy that is consumed in the plant. In many cases this hydrogen is vented. The project demonstrated the PEM Power Plant technology for converting the hydrogen into electricity, heat and water for use in the chlor-alkali production process, lowering its electricity consumption by 20%.

The main project technical results/KPIs are summarized below:

- Integration of heat and power with an existing chlorine production plant

- 2MW power achieved in operation

- Heat available @ 60°C

- Additional treatment hydrogen / air required; H2 scrubber installed

- High net conversion efficiency 50% electric energy on system level and 80% for combined heat and power

- Demonstration of power and heat generation for over 2 years

- On-stream availability of up to > 95% in an operational period for over 2 years

- Influenced by OSBL (H2/grid availability) and stacks but successfully demonstrated end 2017

- Fully automated way of operation and remote monitoring

- Investment demonstrated for €3,000 / kWe

Other results and achievements:

- The plant produced more than 13GWh and made available 7 GWh of thermal energy at 65˚C

- More than 850 tons of hydrogen have been recovered avoiding emission of 15.000 tCO2

- New ME

- As technology production developed (with lower Pt cost)

- Developed open-source calculation tool for preliminary economical assessment.

- Two project workshops successfully organised in China

- Several publications and presentations at conferences.