Modeling activities of the 2-MW cogenerative PEM system

Chlorine industrial production process is energy-intensive in terms of heat and electricity and generates a relevant amount of hydrogen as byproduct; consequently, it is particularly interesting for cogeneration and energy integration by means of fuel cells. The DEMCOPEM-2MW European Project is meant to design and build a demonstrative 2MW PEM fuel cell power plant coupled with a chlor-alkali process, aiming at covering a significant fraction of the industrial process consumptions based on the use of waste hydrogen. Scale-up of stationary fuel cell plants is an ongoing process with many open challenges. Therefore, in the framework of the project, a modeling activity (belonging to WP3: Modeling of process, measurements and evaluation) is developed in order to evaluate the plant expected performances and optimize operational strategies on plant lifetime.

The simulation is built in Aspen PLUS® [1] using available thermodynamic libraries and standard process components and developing customized components for electrochemical and electronic devices. The general modeling approach to the 2 MW plant is aimed to optimizing its operational strategies and evaluating lifetime performance evolution [2]. Calibration and validation of the model have been performed against data from PEM stack installation operating in AkzoNobel’s plant in Delfzijl, where Nedstack PEM fuel cell stacks of the same class used in the projected plant are being tested [3]; and from a 1 MW PEM plant which has been run in in Lillo (Belgium), developed by Nedstack and MTSA with a layout similar to the design of DEMCOPEM-2MW plant.

![4_Polimi [2]](https://demcopem-2mw.eu/wp-content/uploads/2016/04/4_Polimi-2-700x522.jpg) System model is focused on system analysis and employs a specific customized lumped model of the PEM stacks. The fuel cell model calculates mass and energy balances, using regressed polarization curves [2, 4] where the cell voltage is calculated as a function of the ratio to stoichiometry of reactants molar fractions and current density. The model shows errors below 1% when simulating the performances at BOL (beginning of life) and 3% at EOL (end of life) towards experimental data. The real PEM fuel cell is structured in groups of stacks in series and in parallel, in order to reach the desired total power and voltage. The model allows introducing differences for each single stack (e.g. different polarization curves), which are however neglected in this preliminary evaluation.

System model is focused on system analysis and employs a specific customized lumped model of the PEM stacks. The fuel cell model calculates mass and energy balances, using regressed polarization curves [2, 4] where the cell voltage is calculated as a function of the ratio to stoichiometry of reactants molar fractions and current density. The model shows errors below 1% when simulating the performances at BOL (beginning of life) and 3% at EOL (end of life) towards experimental data. The real PEM fuel cell is structured in groups of stacks in series and in parallel, in order to reach the desired total power and voltage. The model allows introducing differences for each single stack (e.g. different polarization curves), which are however neglected in this preliminary evaluation.

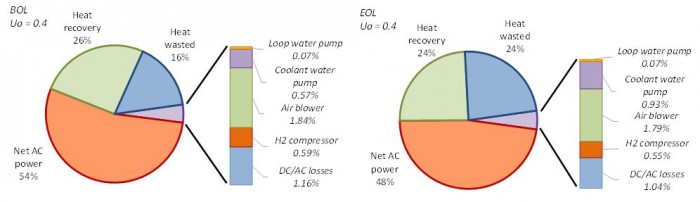

Figure 1: shows the plant layout; the model considers all main auxiliaries, including saturators, heat exchangers, blowers, pumps. Blowers performance curves and lumped characteristics of heat exchangers are included in order to evaluate the impact of part load operation. Figure 2 shows an example of results where the energy balance of the system for a given air utilization factor is evaluated at BOL and EOL, considering the same DC electric output. Electrical efficiency reduction due to cell voltage decay at EOL causes an increase of hydrogen consumption and of the absolute values of the losses.

Figure 2: Energy balance of the plant at BOL and EOL (Ua = 0.4) at constant gross DC power output

The model allows optimizing the plant operation strategies and evaluating the deviations of real plant behavior from theoretical conditions (e.g. supporting in fault detection); over the lifetime of DEMCOPEM project, data from the demonstrative plant will be collected and compared with model results.

Written by:

S. Campanari1, G. Guandalini1, S. Foresti1, J. Coolegem2 and J. ten Have3

1Politecnico di Milano, Department of Energy, via Lambruschini 4A, 20156, Milano

2Nedstack fuel cell technology B.V., Westervoortsedijk 73, 6827 AT, Arnhem

3 MTSA Technopower B.V., Westervoortsedijk 67, 6827 AT, Arnhem

References

[1] Aspen Plus, http://www.aspentech.com/, 2015.

[2] G. Guandalini, S. Foresti, S. Campanari, J. Coolgem, J. ten Have, “Modeling of a MW scale PEM fuel cell power plant integrated in industrial chlor-alkali process”, EFC15133, 6th European Fuel Cell Technology & Application Conference, 2015.

[3] Verhage A., Coolegem J. et al., Int J of Hydrogen Energy 38 (2013) 4714-4724.

[4] G. Guandalini, S. Foresti, S. Campanari, J. Coolgem, J. ten Have, “Modeling of 2-MW co-generative PEM fuel cell for hydrogen recovering from Chlorine industry”, 21st World Hydrogen Energy Conference 2016, Zaragoza, Spain. 13-16th June, 2016.